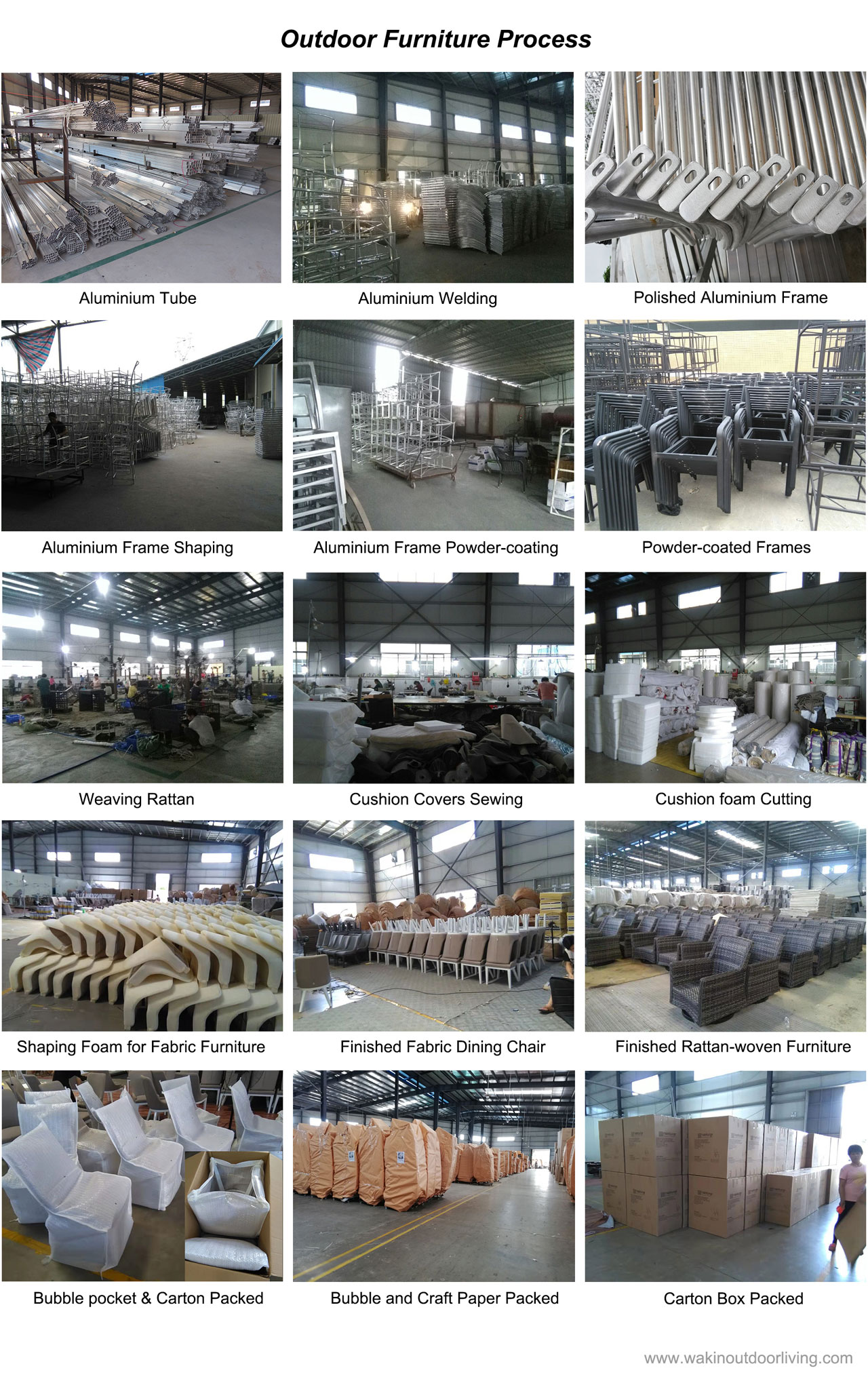

Before we manufacturing aluminium outdoor furniture, the first thing we need to do is select the right materials to process outdoor furniture as customers' requests.

As usual, premium quality PE rattan and strong aluminium tube is our first choice.

High density PE(HDPE) Rattan,which was made of high density polyethylene, not PVC. Its advantages are maintenance free,all weather resistant, waterproof, 100% recyclable, available with or without built-in fire retardant.

Aluminium tube,as you know, rust-proof, corrosion-resistant, lightweight and easy to shape.

>>Welding aluminium frames, we choose full-welded at the main tube, at least 3-spot welding at the branch pipe, which can support the whole structure well.

>>Aluminum frame after forming, we will Polish each corner, screw hole position, etc. , in order to prevent scratches, but also in order to make Rattan more fit, and then shaping, to ensure that the frame is symmetrical, balanced.

>>The next step is powder-coated,powder-spraying and baking paint makes the aluminum material have much higher corrosion resistance, diversified colors and good surface texture and so on.

Weaving rattan is a testing process, it could test if the materials are good enough, also whether the handwork is exquisite or not?

>>If the aluminium frame is not strong enough, the frame will be pulled deformation easily; if the rattan is too bad, it will be pull off easily; if the handwork is not exquisite, the woven rattan will be bent finally. In this case, the finished furniture will be an ugly and perishable and defective goods. That’s why we mentioned as above, we need to choose premium quality materials for outdoor furniture.

Cushion is one of the most important parts for outdoor furniture. Usually, we don't guarantee the quality of the cushions because lots of our customers like to change the cushions frequently and prefer cheap ones. However, there are some high end customers who prefer durable, high elastic cushions, so we offer them the branded fabric such as Sunbrella and Sunproof and high density foam like 28-density, 30-density, even 40-density or quick-drying foam. In addition to the fabric and foam, but also by the influence of the sewing, a good line will affect the shape of a whole cushion, and whether it can match the furniture well.

Outdoor fabric furniture, another kind of popular outdoor furniture in recent years, which is much closer to home and more comfortable. Perhaps many people will worry that the fabric is not suitable for outdoor used, on the contrary, it has the same functions as PE Rattan, four seasons, all weather, waterproof, UV-resistant, mildew and anti-fungus fabric and foam.

Outdoor fabric furniture, we use Sunbrella fabric and quick dry foam t o make it. The same structures is Aluminium Frame.

If needed, textiline is another choice.

Most of customers are paying attention to the packaging, because this will directly affect the appearance and protect product safely well while transportation.

High-end customers will choose carton packaging, before putting into the box, we wrapped the four-sided corner, and then wrapped with a layer of bubble. However, some items can be stacked, for the outer packaging we usually choose to use kraft paper package, the inner packaging as above.

During the process, every step should be inspected strictly to control the whole process, if one step goes wrong, then the whole bulk of furniture goes wrong.